Welcome to our blog post on preventative maintenance for crane machines! If you're in the arcade or amusement industry, you understand the importance of keeping your machines in top condition. After all, downtime means lost revenue and frustrated customers. That's why we've teamed up with Bryan Corbett, the Technical Training and Support Manager at Betson, to bring you expert advice on how to keep your claws running smoothly with minimal downtime.

Now, without further ado, let's dive into Bryan's preventative maintenance guide and learn how to ensure your crane machines operate at peak performance for longer periods.

------------------------------------------------------------------------------------------

Crane Machines are self-merchandising equipment that can earn your business much money. Regular preventative maintenance is one of the best things you can do to maximize your earnings.

Every week, you should be playing with your equipment to test it. Testing consists of the following four steps:

- Credit the crane using the card swipe or money, depending on the machine. This verifies that the game will credit as if a customer were playing it.

- Make sure that the joystick will move the crane gantry in every direction. This ensures that the joystick, main board relays, and motors all work together. You should be able to move to each corner of the playfield.

- Drop the claw and make sure it closes. Make sure that it can lift the prizes that are in the crane.

- Verify that the prize counter advances when a prize is awarded, which is essential to compute the cost of merchandise given away.

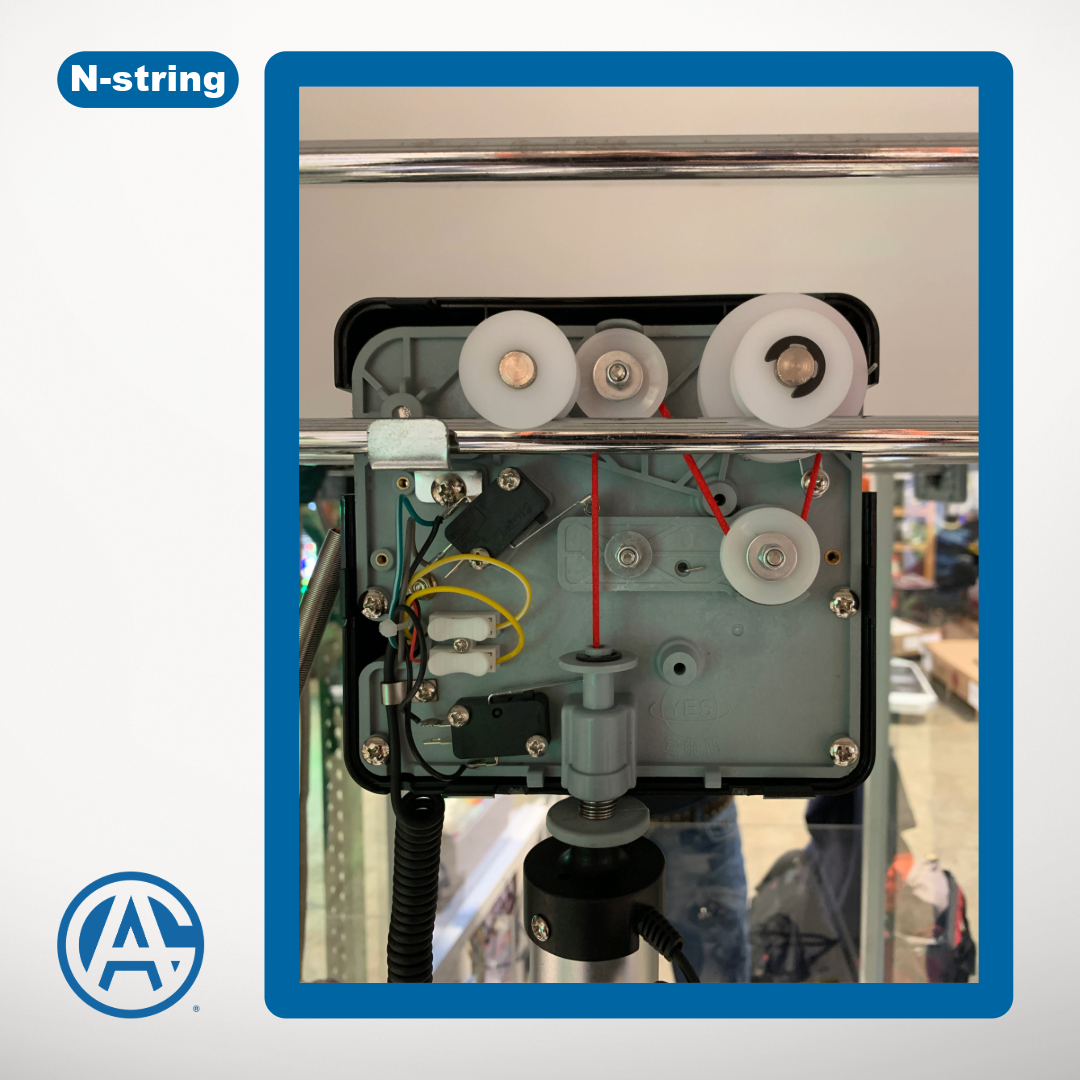

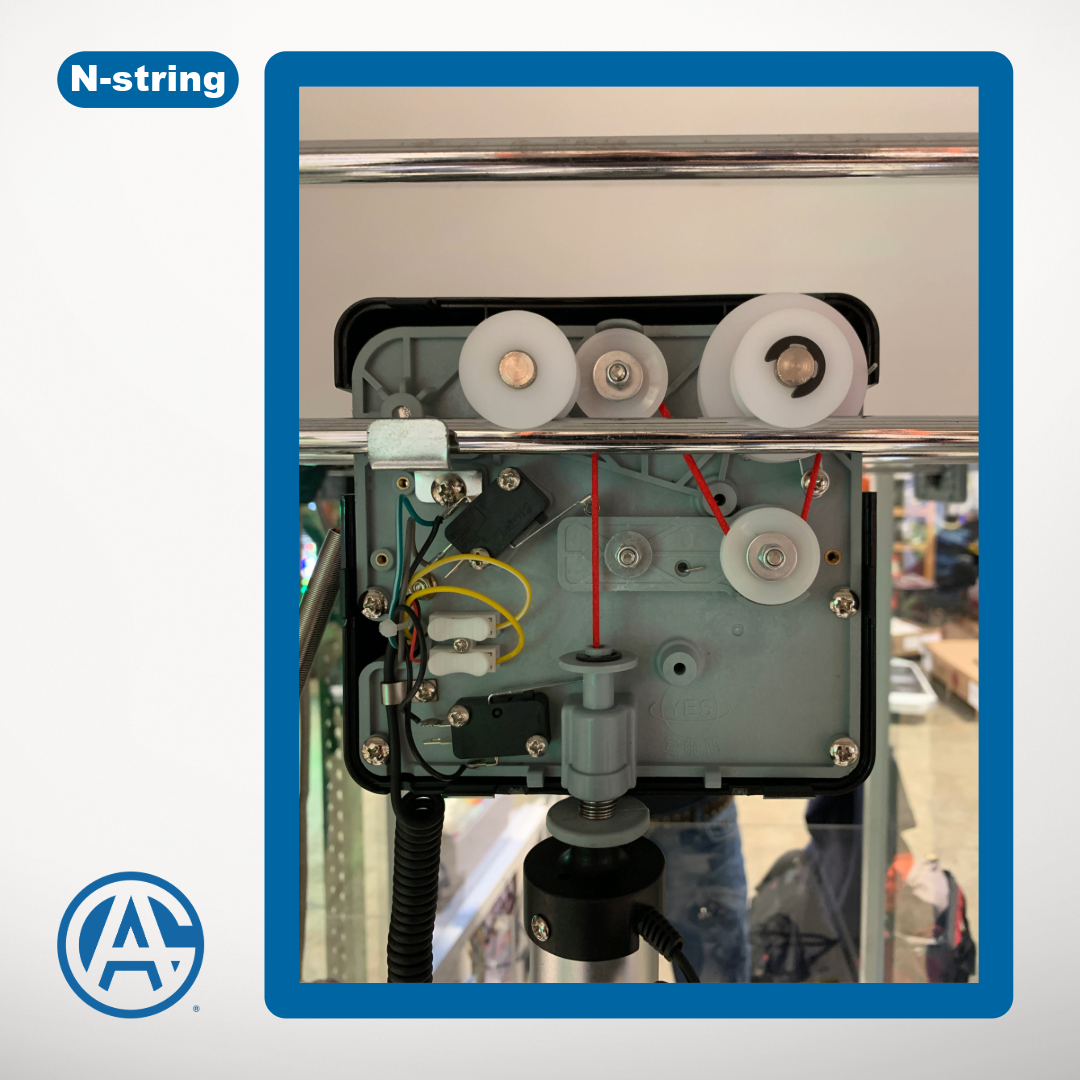

In addition, to play testing your cranes, you should remove the cover of the claw carriage and examine the condition of the string and the string path. Players often get excited when playing and hit the button to drop the claw immediately. This results in the string unwinding completely and then rewinding backward, which causes much bizarre behavior. Switches are activated incorrectly, and the claw could close before it reaches the bottom of the crane. Most crane machines you encounter will have the string path as pictured below.

The string forms the letter “N”. It comes up from the claw, goes over the top middle pulley, and then goes under the pulley that pivots on the spring arm. It is finally wound up on the cord spool, coming up on the right side of the spool. If your string comes up on the left side of the spool or is not going around both pulleys, you will have problems with the crane operating correctly.

Make sure that the string is not dirty, worn, or fraying. If the string looks ragged, replace it. Do not attempt to cut bad parts out of the string. Tying knots in the string will cause problems with the machine. Shortening the string by removing bad parts will result in the string winding up backward. Make sure you have replacement string on hand at all times. Most cranes come with a small supply of replacement string.

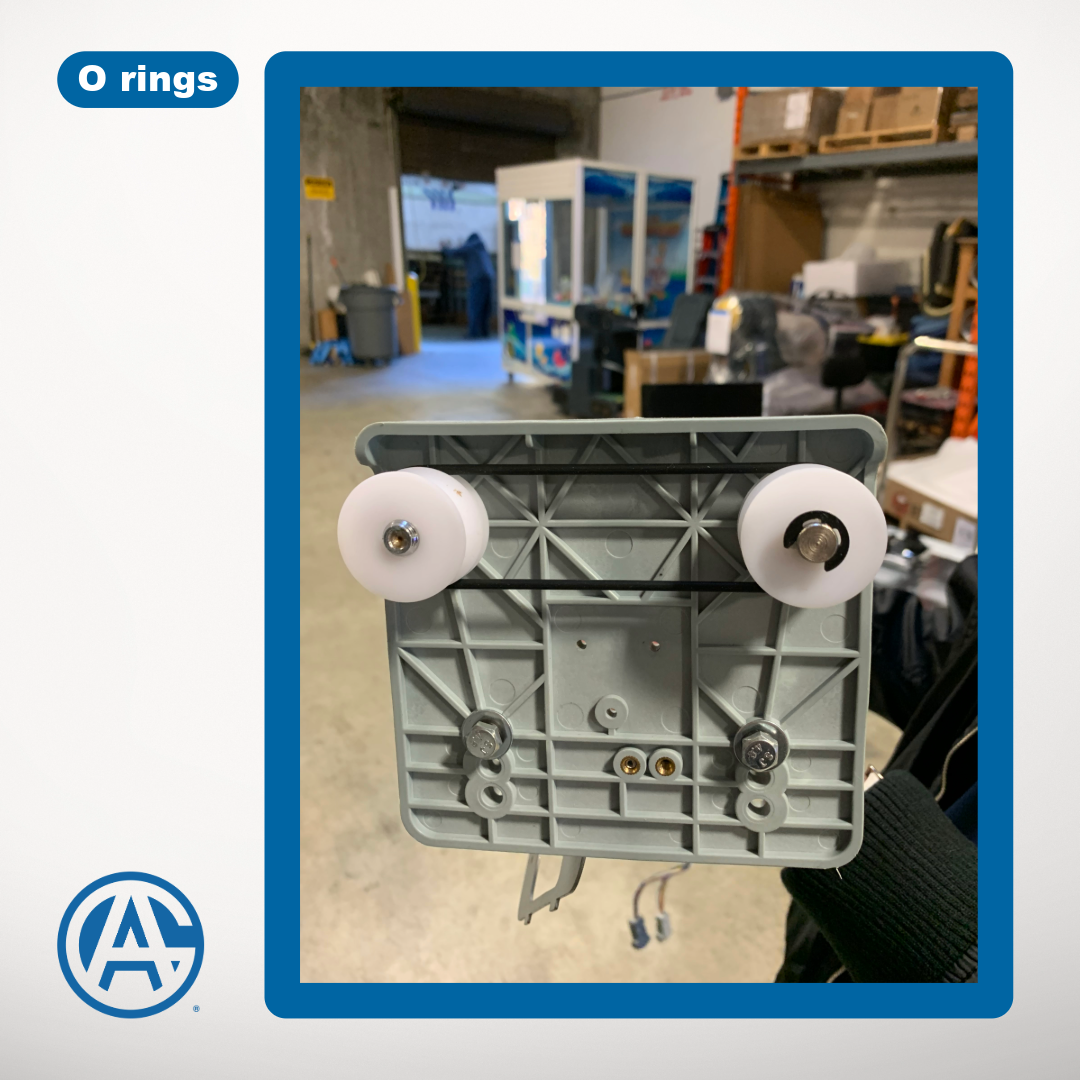

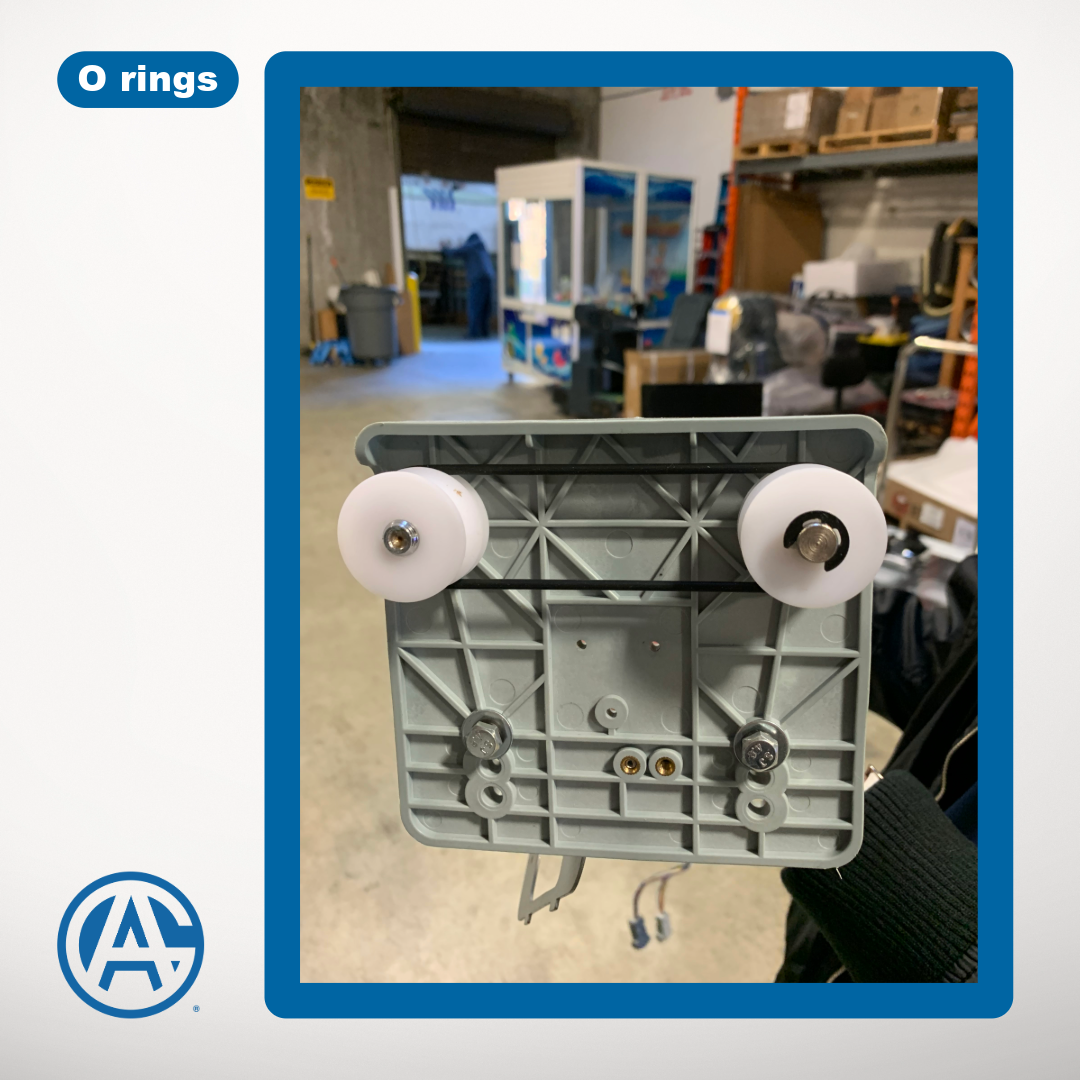

Most cranes also have rubber belts or O rings that keep the drive pulleys and idler pulleys moving at the same speed. When these become worn or broken, it can cause the crane gantry to get wedged into place or even fall into the machine. There should be metal brackets that keep the gantry from falling off of the rails, but you would be surprised how often employees remove these.

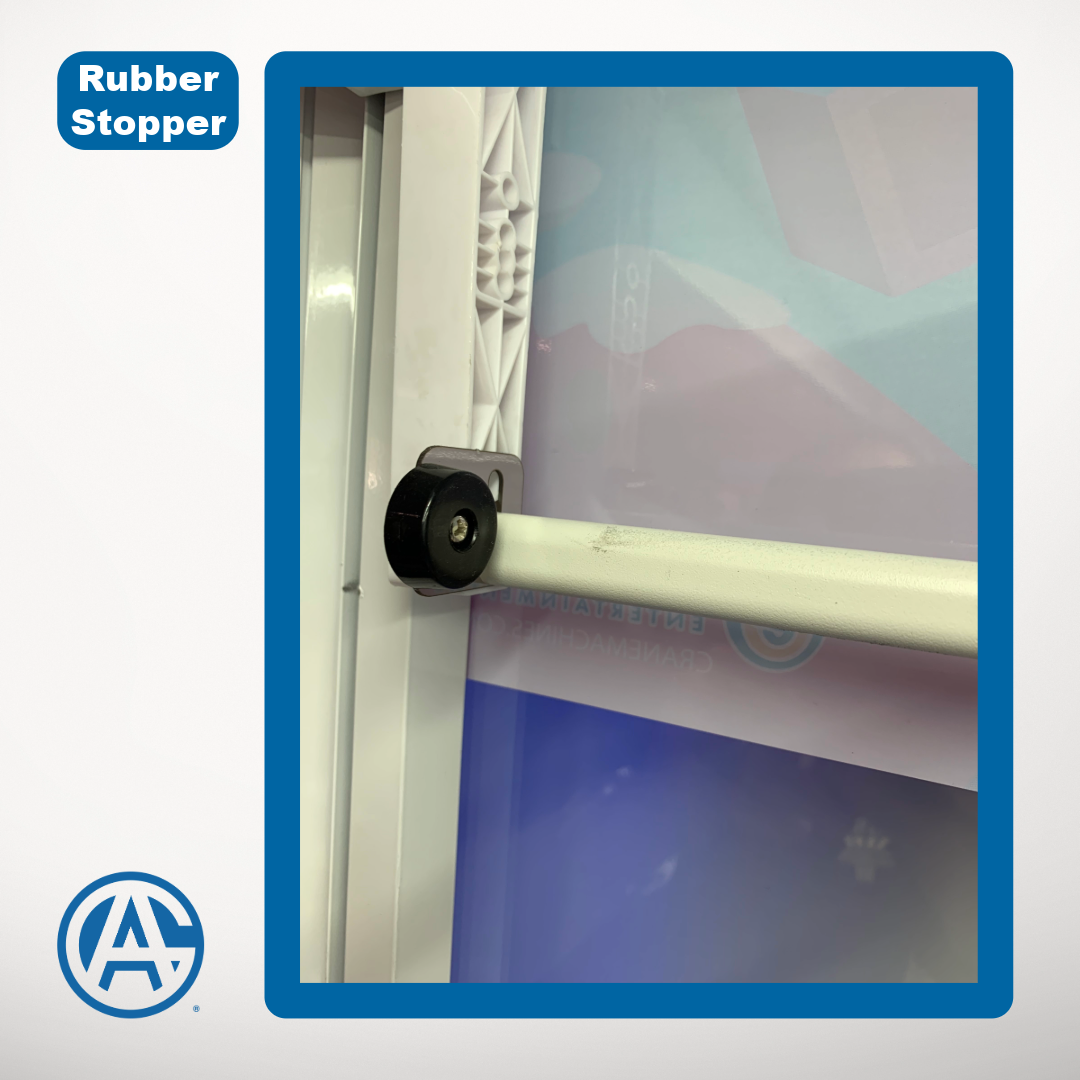

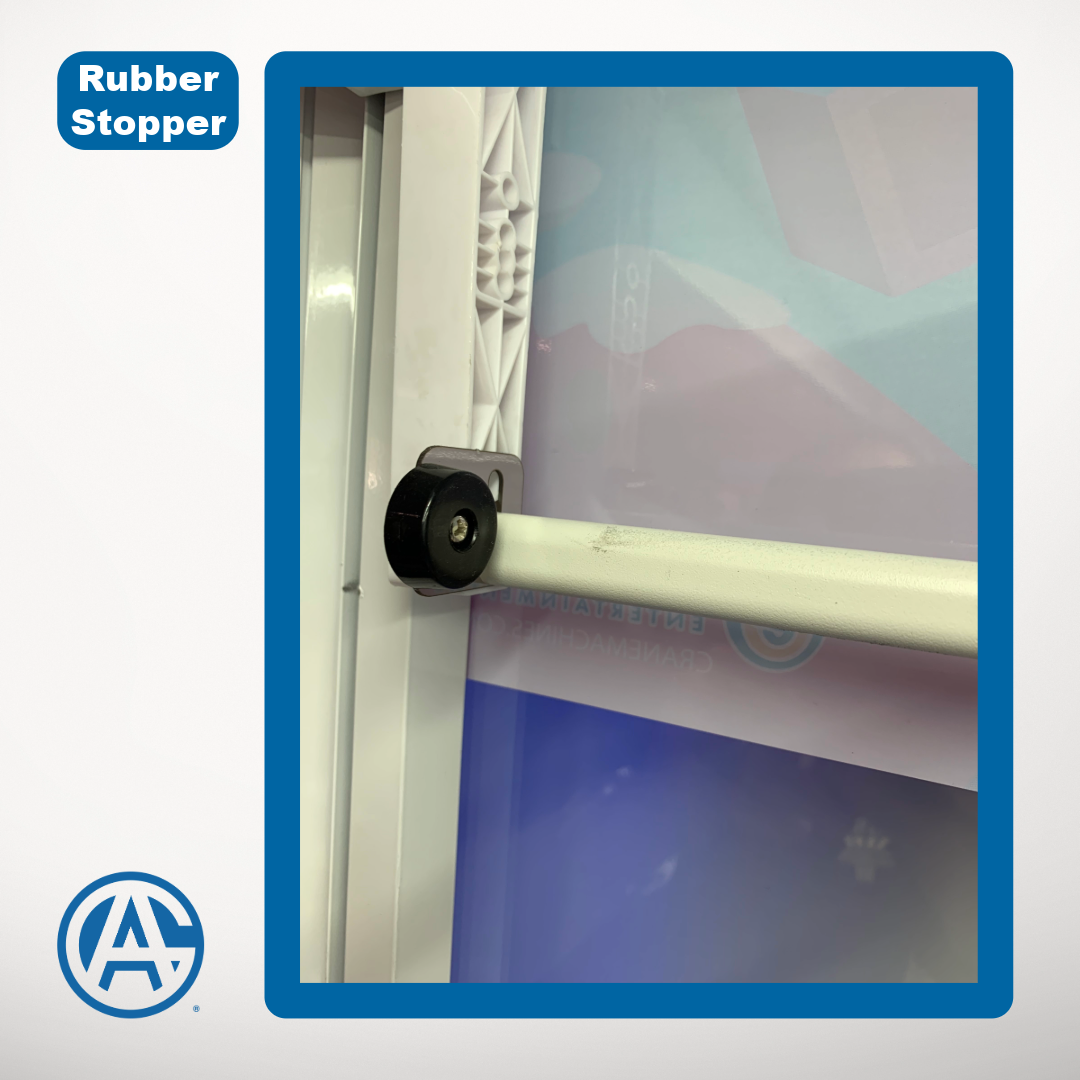

The following three pictures are all part of the same subsystem. Microswitches with roller arms tell the machine to stop the motors when they reach home positions. You will often have a motor error on the crane, but the problem is the limit switch. Make sure that all wires are attached to the switches correctly. You may have to bend the roller arm back into shape periodically. After many uses, the roller arm of the switch will bend into a position that does not activate the switch at the right time. (Sometimes not at all) Try not to bend the switch arm drastically at a single point. Use two or three points along the arm to bend it more gradually.

There are often rubber pads that can be screwed into the cabinet or even just attached with adhesive. These can fall out of place and not activate a switch. Examine the switches and observe them being activated properly.

Crane machines get much use (and abuse). The constant vibrations from the motors can cause many screws or other components to shake loose. Overtightening the screws to attempt to prevent them from coming loose will cause the warping of parts. Instead of overtightening, use a small amount of red Loctite thread locker to hold screws in place.

These are just some of the fundamentals of preventative maintenance for a crane machine. Make sure to read the manual of each model of your crane. The manufacturer often has preventative maintenance guidelines and troubleshooting suggestions to help you maintain your machines and achieve peak earnings.

------------------------------------------------------------------------------------------

About the Author(s): Clint Novak is the Business Development Manager at A&A Global Industries, a leading supplier of amusement and vending industry products. With over a decade of experience in the amusement industry, Clint is passionate about empowering arcades through innovative branding strategies.

Bryan Corbett, the Technical Training and Support Manager at Betson.